- With an AI solution that reduces the battery cell design process to one day, LG Energy Solution showcases its technological leadership.

- Integration of generative AI technology enhances LG Energy Solution’s operational efficiency.

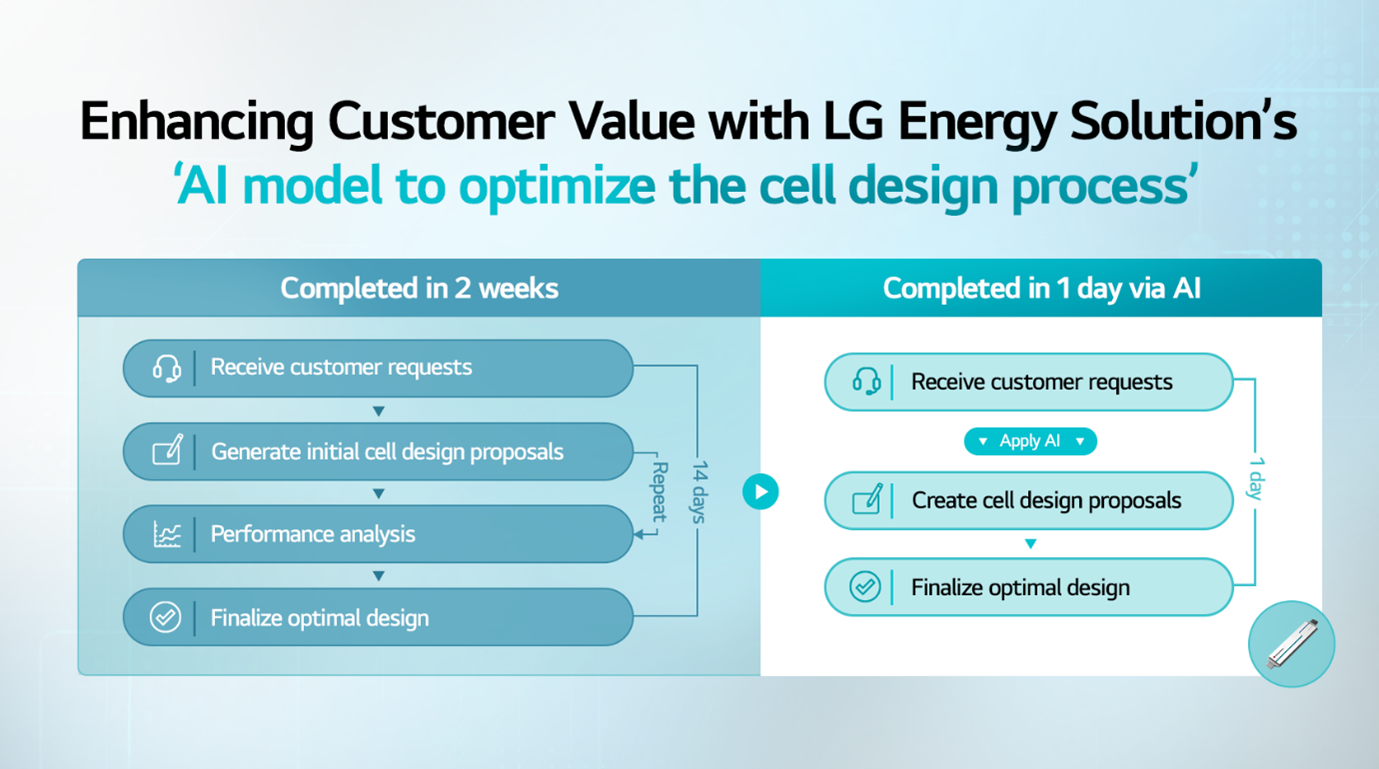

The first crucial phase of making a battery is designing the cell, which traditionally takes weeks to complete. That’s why LG Energy Solution has developed an artificial intelligence (AI) solution that streamlines the process, reducing design time to just one day. With the assist of an AI model, LG Energy Solution is optimizing cell designs to meet each customer’s performance needs, thereby enhancing customer value and maximizing battery efficiency.

Specifically, LG Energy Solution has invented the ‘AI model to optimize the cell design process.’ This AI model is designed to create the best battery cell designs in just a day based on customers’ required performance criteria. This involves determining the ideal composition of battery cells to meet key factors like capacity, energy density, and resistance as requested. By reducing the two-week wait to just one day, LG Energy Solution is able to manufacture high-performance batteries more swiftly and precisely than ever before.

Previously, battery cell designers had to iteratively modify the design and evaluate its estimated performance. However, courtesy of its newly developed AI recommendation model, LG Energy Solution can now input its desired specifications and generate the optimal design solution immediately. Even after validating these AI-generated designs, the entire process can be finalized within one day. LG Energy Solution expects this groundbreaking AI solution will significantly improve its cost and operational efficiency, enhancing market competitiveness through rapid and precise battery cell design.

The development of this new AI model is evidence of LG Energy Solution’s extensive technology leadership and expertise, which spans over 30 years. It’s also a clear reflection of its accumulated experience in designing solutions for a wide array of important clients, which has been instrumental in developing this AI model. For instance, LG Energy Solution utilized generative AI technology to train approximately 100,000 cell design drafts for the generation of its own battery design algorithms.

LG Energy Solution aims to integrate the AI model into its internal cell development system as early as October and is currently strengthening the system through pilot implementations. LG Energy Solution also plans to actively apply AI to improve other elements beyond battery cells, such as module and pack designs, in the coming years.

AI’s greatest advantage is its ability to design battery cells consistently and quickly, irrespective of the designer’s skills. By integrating AI technology into our cell designs, which determines battery performance, LG Energy Solution aims to provide overwhelming product competitiveness alongside differentiated customer value.

Meanwhile, LG Energy Solution is establishing a ‘Generative AI Platform’ by introducing generative AI technology to effectively leverage employee expertise across various other areas of business including procurement, production, processes, facilities, and quality management.