- Head of LG Energy Solution North America speaks at major regional conference and shares roadmap to EV adoption.

- Presentation highlights the company’s ambitious plans to lead North America’s EV transition.

- Advancing sustainable technologies, LG Energy Solution commits to making reliable EVs accessible to all.

(Source: Rho Motion Live: North America 2024)

On October 2-3, experts and visionaries across the EV, battery, charging, and infrastructure sectors converged in Columbus, Ohio for Rho Motion Live: North America 2024 – a two-day conference hosted by renowned battery research institution Rho Motion. This major event delved deeper into the intricacies, challenges, and promising opportunities that are poised to shape the future of these industries.

Among the prominent voices to take the stage was Robert H. Lee, Corporate Executive Vice President and Head of North America at LG Energy Solution, who presented the “Turbulent but certain path towards electrification” where he shared his thoughts on the unstoppable and dynamic shift towards an electrified world.

At this event, which covered topics from the North American EV battery landscape to battery technology roadmaps, Lee shared LG Energy Solution’s perspective of the outlook for the EV market and its evolution, before discussing the major barriers to electrification and the industry’s efforts to overcome them. Also, as CEO of L-H Battery Company, the joint venture (JV) between LG Energy Solution and Honda based in Ohio, Lee highlighted some of the company’s major investments in North America, particularly in the state of Ohio.

While the current pace of electrification may fall short of predictions made four to five years ago, Lee emphasized that the global shift to EVs is still inevitable. However, given the magnitude of this transition and consumer acceptance, Lee emphasized the importance of bringing reliable and affordable EVs to the market. “The first generation of EVs that hit the US market — many of them were in excess of $75,000 and it was really a niche product,” he said.

As conversations surrounding range anxiety and the need for a robust charging infrastructure continue, such elements must be addressed alongside market growth to support the widespread adoption of EVs.

For most everyday driving in the U.S., EVs only need to be charged once a week. However, for long-distance driving across states or rural areas, EVs may feel slightly unequipped to handle the journey until the charging infrastructure catches up. To give people the confidence to travel comfortably, even on long trips, charging stations must become nearly as widespread as gas stations. Additionally, the EV market must be filled with more affordable, budget-friendly models with extended ranges. Safety is also a key issue, and Lee emphasized that LG Energy Solution is actively working to address these priorities and fully dedicated to advancing electrification.

Lee has set the industry a goal of achieving USD 30,000 EVs with a 300-mile range. “Delivering these vehicles in large numbers is key to unlocking the market’s potential. This should be a central focus for the industry as a whole,” he said.

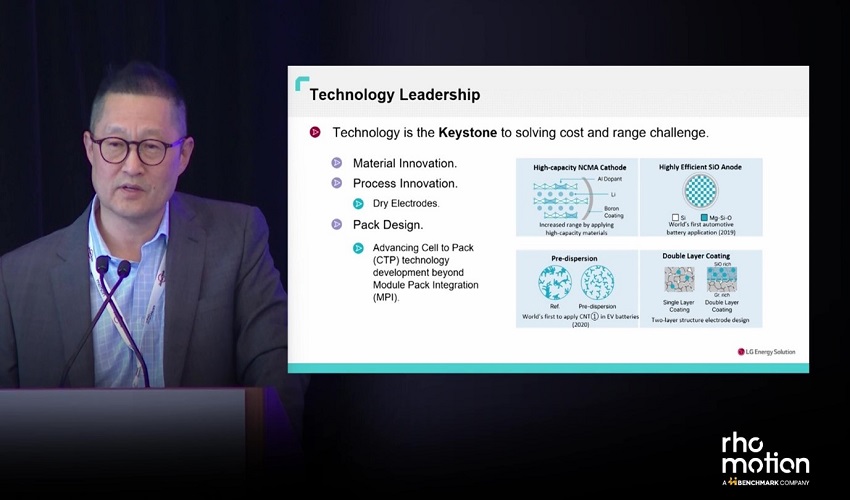

To realize this vision, LG Energy Solution is implementing strategies to lower the cost of vehicle production and, as a result, the price of EVs. Current efforts include doping aluminum into NCMA cathodes to increase energy density and exploring high-energy-density silicon anodes. This involves a concept called pre-dispersion, the process of mixing powder so that all fragments are as finely and evenly distributed as possible, avoiding clumping to maximize energy density.

To prevent particles from clumping, LG Energy Solution applies double-layer coating technology when coating cathode materials onto aluminum foil to form two distinct layers. The first layer adheres closely to the surface to enhance quality and productivity, while the second layer uses a high-energy-density material to maximize energy output without sacrificing efficiency. This approach also contributes to lowering production costs.

Dry electrode technology is another breakthrough by LG Energy Solution, with plans to apply it to mass production by 2028. Solid-state battery is another exciting innovation in development and a key area of focus for the future.

“LG Energy Solution’s primary goal is to prepare operations to meet customer demand while driving continuous improvements, both large and small, to make batteries more economical through a range of pioneering technologies,” Lee said.

During the Q&A session that followed, Lee also addressed the cost-effective potential of a high-voltage mid-nickel battery strategy, which is a key focus for LG Energy Solution’s next-generation EV technology.

While high-nickel batteries with 80-90% nickel content have dominated the market, LG Energy Solution is now shifting its focus to a high-voltage mid-nickel battery solution. This configuration offers a high level of energy density without adding excessive weight and overloading the vehicle, making it possible to deliver a more cost-effective solution. Lee emphasized that the company is working closely with several OEM partners to develop products that strike the right balance between safety and cost efficiency, instead of solely attempting to push the limits on performance by maximizing energy density.

Lastly, Lee highlighted LG Energy Solution’s activities in North America, which includes three JV plants with General Motors (GM), one with Honda, one with Hyundai, and one with Stellantis, in addition to two wholly-owned plants. Its wholly-owned Michigan plant, which became North America’s first gigawatt-scale battery facility when it was built in 2012, has extensive experience in the U.S. Just few years ago, the company announced another 100%-owned plant in Queen Creek, Arizona, dedicated to cylindrical cell battery production.

In particular, LG Energy Solution is collaborating on two battery facilities in Ohio. The Lordstown facility, known as Ultium Cells, is a 40 GWh JV with GM, while a similar-scale facility is being developed in Jeffersonville with major Japanese automaker Honda. Each plant is expected tol create between 2,200 and 2,500 new jobs over the coming years.

“You saw the level of investment we’re making here in North America,” said Lee. “We’re going to be accounting for about 50% of battery capacity here in North America once we finish building our plants. We’re very committed to this market and look forward to working with many of you to drive this transformation.”

(Source: Rho Motion Live: North America 2024)

+ To stay up to date with the latest news from LG Energy Solution, click “Subscribe.”