- LG Energy Solution establishes Future Technology Center to further innovate and develop the battery industry.

- Committed to commercialization of advanced batteries by developing process technologies

[Technology Leadership Series 2: Next-Generation batteries and Future Industry Preparations]

In 2023, LG Energy Solution invested KRW 1.04 trillion (USD 819 million) in R&D, marking an 18.4% increase over the previous year. This investment highlights LG Energy Solution’s commitment to innovating and advancing the battery sector.

Late last year, LG Energy Solution took a big step forward by establishing Future Technology Center under the leadership of the new CEO David Kim. It’s part of the company’s efforts to accelerate its R&D on next-generation battery technologies, as it shifts attention to developing and commercializing advanced batteries for various applications. This includes semi-solid and solid-state batteries, lightweight lithium-sulfur batteries, and lithium-metal batteries.

In a demonstration of its commitment to developing and commercializing next-generation batteries, LG Energy Solution appointed Vice President Geun-Chang Chung, an automotive battery expert with 30 years of development experience, as head of the Future Technology Center.

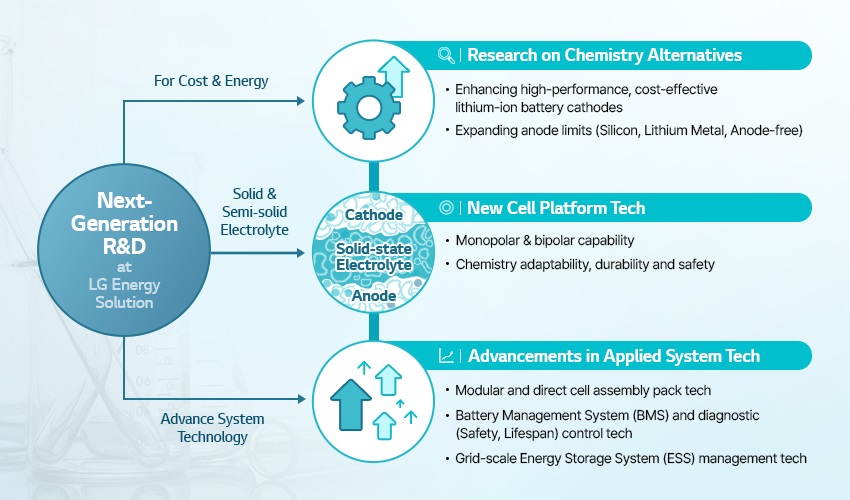

LG Energy Solution is now developing next-generation batteries technology under his leadership, while continuously improving upon its lithium-ion batteries to differentiate customer value it offers across various EV segments. One way it’s differentiating products is by enhancing material technologies to meet future market needs in terms of safety, durability, cost competitiveness, driving range and fast charging.

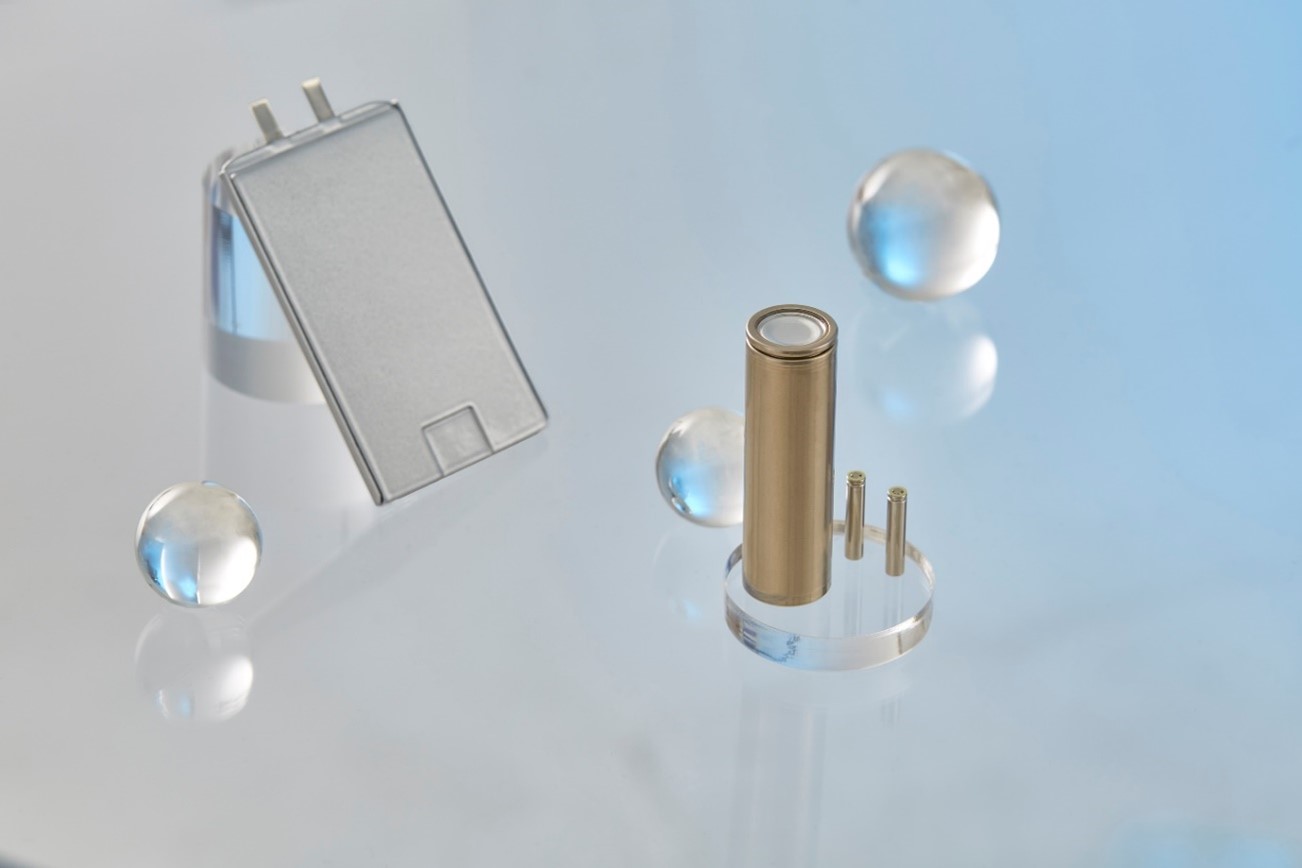

In pursuit of more innovative manufacturing processes, LG Energy Solution is developing dry electrode technology which improves performance, quality, environmental impact, and costs, to be applied to lithium-ion and next-generation batteries. What’s more, LG Energy Solution is leveraging existing assembly techniques and equipment used for pouch and cylindrical cells to expand next-generation cell applications and scale up faster.

Lithium-sulfur batteries, which have gained attention from several markets due to their gravimetric energy density, are a perfect fit for the aviation industry. On the other hand, solid-state batteries, powered by LG Energy Solution’s proprietary technology, utilize high-conductivity electrolytes and cathode nanocoating to boost stability, power, and durability, all characteristics that make them ideal for high-end EVs. The gravimetric energy density limits of lithium-metal batteries have also been extended by increasing energy density through a smaller, lighter, and longer-lasting form.

As battery technology advances, the development of system technology becomes even more essential. LG Energy Solution is commercializing pouch type Cell to Pack (CTP) technology with simplified modules and enhanced safety, and is working towards developing simpler and safer systems with next-generation cells. Additionally, it is introducing battery safety and lifecycle management technologies through application services like Battery Management System (BMS), Cloud services, and Battery-as-a-Services (BaaS). These innovations afford users peace of mind and cost-effective battery usage through safer and longer-lasting batteries.

To achieve all this, LG Energy Solution must solidify its technology leadership in the market. This is why it is enhancing its premium high-nickel NCMA product capabilities and accelerating the development of high-voltage mid-nickel NCM and LFP battery technologies, targeting the mid-to-low-end market while adapting its product portfolio to meet customer needs across all segments. Furthermore, in the small battery sector, LG Energy Solution plans to begin mass production of its 46-Series batteries in the second half of 2024. As for the ESS business, it will expedite to ramp up its LFP product offerings and expanding its integrated solutions.

LG Energy Solution is securing structural cost competitiveness that remains resilient against external risks. By expanding the scope of direct raw material procurement, changing key materials through technological development, and strengthening direct investment in the supply chain, it is enhancing its fundamental cost efficiency. Alongside this, it is improving productivity and quality, reducing fixed costs based on smart factory principles, and implementing plans to rationalize operational expenses including logistics and utilities.

To ensure sustainable growth, LG Energy Solution has focused consistent and efficient R&D efforts on securing its technology leadership. This involves developing new materials, adopting material informatics using AI and focusing on R&D utilizing virtual verification and digital twins.